Who We Are

At Harvest CROO, we are transforming automated agriculture with our extraordinary set of technologies.

We provide a harvesting service that automates the crop management, harvesting and packing of specialty crops, and we have started with strawberries.

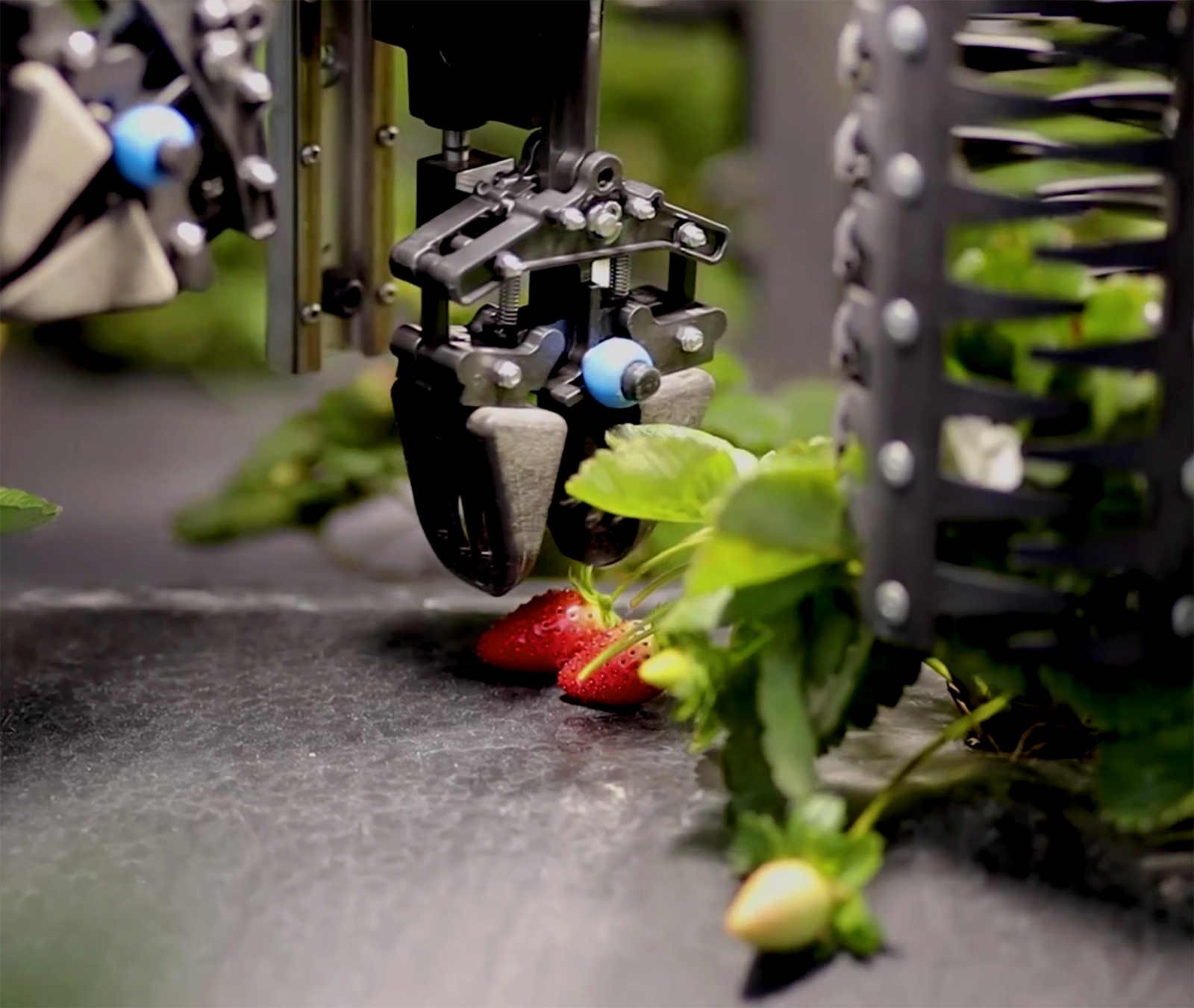

Harvest CROO robot about to pick a ripe strawberry

Harvest CROO is supporting strawberry growers and maintaining supply of nutritious foods with environmentally friendly harvesting

Why is automation a critical need in harvesting?

Strawberry growers and the global agricultural community as a whole has been confronted with the fact that the current and future demand for food cannot rely on human-only cultivation and harvesting.

While this has been commonplace in grain-based fields for decades, other food crops such as fruits and vegetables have distinct challenges that have limited the amount of machine harvesting technologies available that guarantee the pick quality, ripeness accuracy and food safety needs.

Global Population Growth

Harvest CROO is